Custom Parts Manufacturing

Providing you with one-stop custom manufacturing solutions in China.

- Discounted prices, save up to 30%

- Fast delivery within 6 days

- Accuracy tolerance up to +0.005 mm

- Global distribution with reliable logistics network

Various manufacturing processes of parts

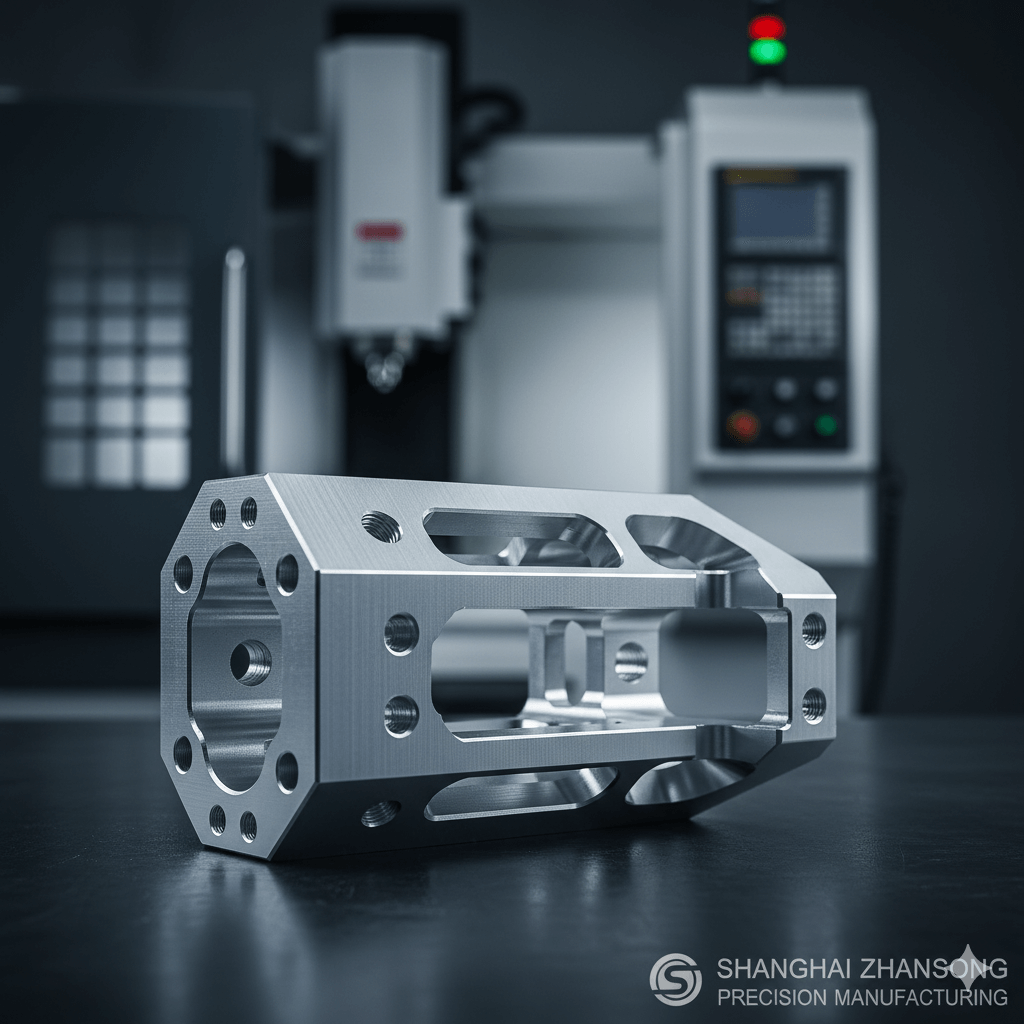

CNC milling service

zs has invested in the most advanced 3-axis, 4-axis and 5-axis linkage machining centers, which can process parts from multiple angles, reduce the number of clamping times and ensure the highest precision. Whether your requirements are precision parts made of aluminum alloy, stainless steel or titanium alloy, the ZS professional team can turn your CAD drawings into reality

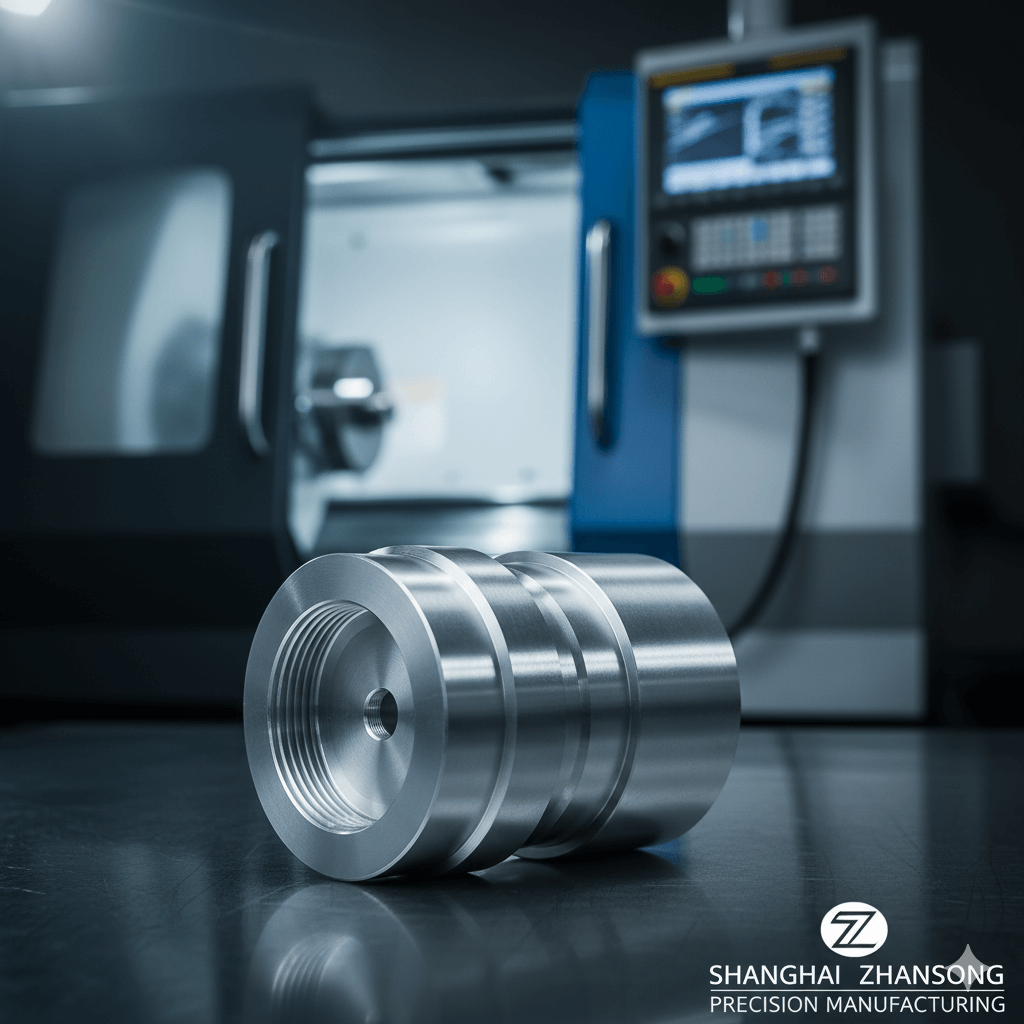

CNC Turning

High-precision CNC turning services, specializing in the production of cylindrical parts with outstanding concentricity and surface finish. Our CNC lathes are equipped with power tool turrets and can perform turning and milling compound processing. With a single clamping, complex features such as drilling, tapping and milling can be completed. This greatly enhances efficiency and ensures the absolute accuracy of customized shafts and connectors

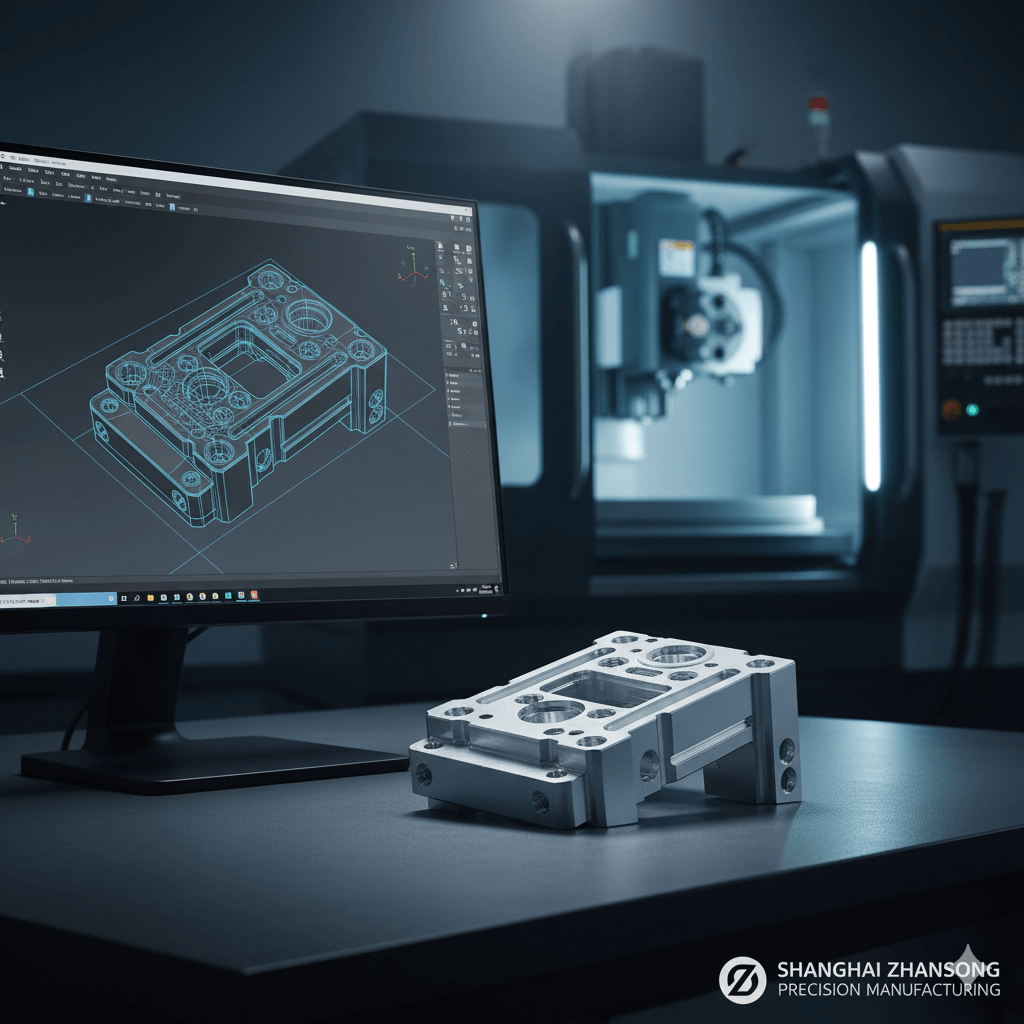

Rapid Prototyping

Accelerate your product development cycle with our CNC rapid prototyping service. We deeply understand your requirements for speed during the Design Verification (DVT/EVT) stage. This is why we promise to offer "5 days of free samples". Unlike 3D printing, our CNC prototypes are manufactured using exactly the same materials and precision as the final production, ensuring 100% accuracy of your functional tests.

Surface Finishing

We offer surface treatments such as laser engraving, polishing, powder coating, anodizing, painting, sandblasting, grinding, galvanizing, chromium plating, etc. Surface treatment services enhance the appearance and durability of parts, ensuring they meet your specifications.

Unlock Precision Engineering Today

ZS is dedicated to providing precision CNC parts, ensuring that every processing procedure meets the highest standards. Our advanced equipment is capable of manufacturing parts of various complex shapes with an accuracy of ±0.002mm. Whether you need single-piece production or mass production, it’s our expertise. Learn how we can turn your design into reality.

Easily fulfill your customized requirements

Sample & Drawing

Upload your CAD/STP/PDF drawings and inform us of the materials, quantities and tolerance requirements.

Get Quotation

Our team of engineers reviews the drawings, offers free quotations and manufacturability analysis.

Sample Production

Our factory supports low-volume production and sample prototyping—ideal for small businesses and new distributors.

Mass Production

ZS has excellent mass production capabilities, supplying 5 million parts per year. We will set up your seamless production, keeping track of quality control and more.

Shipping

We will help you organize optimal shipping to your business location or a warehouse. We ship worldwide.

Why ZS Can Be Your Premier Supplier

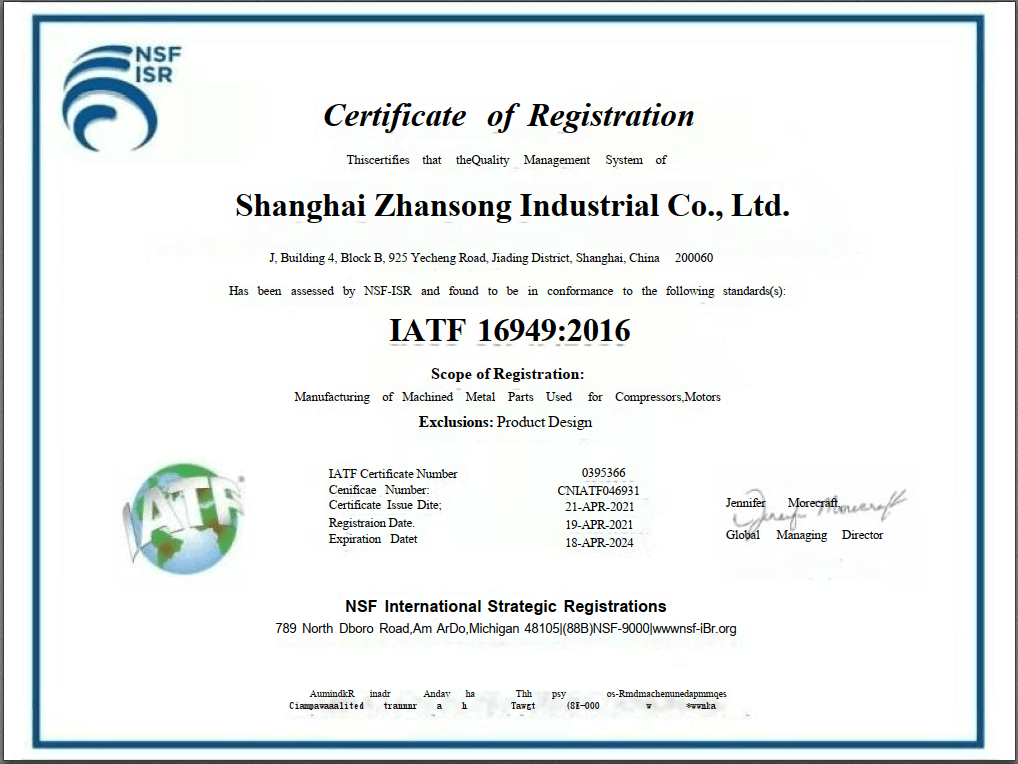

Quality Assurance

We adhere to ISO 9001 standards, ensuring top-quality processes and outcomes.

Advanced Machinery

Our capabilities include 5-axis CNC machining, providing precision and versatility.

Expert Team

Our engineers bring years of experience and expertise to every project.

Fast Response

We offer 12-hour quotes and deliver samples within 5 days.

Engineers Who Trust U

We were very impressed by the parts we received. The tolerance requirements were very strict, but the ZhanSong Industrial (ZS) team perfectly met our drawing requirements. The surface treatment is excellent, and the quality control is obviously done very well. We highly recommend any project that requires high precision.

A precision instrument manufacturer in the United States

One of the things we are most worried about is that precision parts may be damaged during cross-border transportation. ZS has done an excellent job in this aspect. Each part is properly protected and independently packaged, and the box is very sturdy. All the goods arrived intact, which saved us a lot of trouble.

A German auto parts purchaser

From inquiry to delivery, the entire communication process was very smooth. Their responses are always both prompt and professional. We were deeply impressed by the “5-day sample” service they promised, and the final bulk goods were delivered exactly on time. They are a very reliable partner, which makes us very confident about the progress of the project

A new technology startup in Canada

Our solutions are highly trusted by customers

We have been providing services to customers from Germany, the United States, Japan and other countries for a long time. Our products are widely used in the fields of automobiles, medical devices, aerospace and industrial robots

Here’s a glimpse of who we collaborate with:

Frequently Asked Questions

What Materials Can You Process for CNC Machining?

ZSCNC processes different metal materials such as:

Aluminum Alloy: Al 6061, ACD12, A380, Al6063, Al6082, Al075, etc.

Stainless Steel: SS303, SS304, SS316, and more

Brass: Brass 59-1, Brass Free-Cut 360, and so on

Zinc: Zamak 3 and Zamak 5

We can also process materials such as carbon steel and copper.

Do You Support Sample and Mass Production?

Yes. ZSCNC supports sample-prototyping as well as low-volume manufacturing. We also offer mass production that allows us to supply more than 4 million CNC machined parts per year.

Can You Help With Our Product Design?

Of course, ZSCNC can help you. We have expert R&D engineers who have rich experience in CNC machined parts and structures. You can communicate with our team or send us your inquiries.

Do You Offer Customize Products and Services?

Yes. Our R&D team will handle all your specific requirements. You can send us your drawing or CAD file so we can help you. Aside from that, we can also provide you with samples and wait for your approval. We will make sure that everything will be produced according to your specifications.

What Surface Treatments Can You Handle?

ZSCNC can handle different surface treatments such as anodizing, polishing, chrome-plating, sandblasting, electropolishing, and more. We can provide different surface treatments based on the materials used. exercitation.

If the Product has an Issue, Can I Request for Refund or Replacement?

Yes. If the parts or the products are damaged due to bad packaging or other factors caused by our business, we can provide refund or replacement.

What is your minimum order quantity (MOQ)?

We are very flexible. We accept orders for mass production ranging from 1 rapid prototype sample to over 10,000 pieces. No matter what the scale of your project is, we are willing to quote for you.

What is your standard delivery time?

Our rapid prototype samples can be delivered within 5 days at the earliest. The delivery time for mass production will depend on the complexity and quantity of the parts. We will provide you with the most accurate delivery date when quoting.

Which drawing formats do you accept?

We accept the vast majority of CAD files, including.step,.iges,.x_t,.dwg,.dxf, and.pdf. For the fastest and most accurate quotation, we strongly recommend that you provide the 3D model file.

How Long Does Your Quotation Take?

Usually, after your send your requirements, it will take us one day to estimate a quotation.

Do You Ship Worldwide?

Yes. We can ship worldwide through DHL, FedEx, and UPS. We can ship by air, land, and sea.

How Long Can I Receive My Orders After Shipping?

Delivery may usually take 4 to 8 days. However, it also depends on your order quantity.